Tank heads

Manufacturing dished heads

DVAI heads and bottoms are produced in a cold forming process.

We produce heads and bottoms:

– through dishing and flanging forming processes, with diameters of up to 4500 mm and wall thicknesses of 22 mm,

– through spinning forming process, with diameters of up to 1500 mm and wall thicknesses of 6 mm.

DVAI is a company engaged in the business of cold forming dished heads for tanks, boilers, industrial equipment.

Our customers belong to different industrial sectors: Petrochemical, chemical, pharmaceutical, cosmetic, agro-food, logistics, transports, tanks, water treatments, environment, industrial boiler, heat exchangers, etc.

We manufacture a large range of dished heads and cones to varying shapes and standards: Torispherical head or bottom, Klopper heads (DIN-28011), Korbbogen heads(DIN-28013), spherical caps, flat heads, Flanged only Head, dished heads for low pressure, spherical covers, diffusion heads, cone heads, Cones for Pressure Vessels, PRC heads(NFE 81-101), MRC heads (NFE 81-104), GRC heads(NFE 81-102), elliptical heads 1,9:1 (NFE 81-103), elliptical heads 2:1(ASME), hemispherical heads, Shallow Head, Inverted Dished heads and Inverted Cones…

French manufacturer of tank heads

DVAI is the only French tank heads manufacturer which has in its workshops the stock of stainless steel sheets and forming machines (dishing, flanging and spinning forming).

DVAI manufactures Heads according to PED 97/23 EC for pressure vessels. The stainless steel material is certificated according to Pressure Equipment Directive (97/23/EC).

The dished and flanged heads are manufactured with PED/ TÜV standard plates aiming the production of pressure machines.

We proceed according to the following manufacturing laws: CODAP, ASME, ADM.

DVAI manufactures stainless steel tank heads, in order to avoid any pollution from other materials. This point represents another guarantee of quality for all our clients.

Thanks to its permanent stainless steel stock of more than 1000 tons, DVAI is able to launch immediately the manufacturing of your dished heads. This is another guarantee of a mastered final deadline.

The openings can be made until the day before the dished heads’ departure. Thus, you can specify us the openings’ positions until this moment. This point is another proof of DVAI’s flexibility.

Referenced norms:

Dished heads are manufactured according to the following norms:

– NF E 81-100 December 1997 – Dished heads, designation, tolerances.

– German tolerances DIN28011 et DIN28013

Different steps to manufacture a dished head

Each step is realised within our workshop in Tournan En Brie, France :

- Calculation of the disc’s diameter

- Disc cutting

- Disc welding, in case of disc in several parts

- Destructive or non-destructive controls (if requested in your order)

- Cap pressing process and control of the knuckle radius

- Knuckle radius forming and knuckle radius control

- Edge machining according to NFE 81 110

- Dished head control at the end of the manufacturing process

- Dished head pickling

- Dished head polishing (if requested in your order)

- Openings (if requested in your order)

- Final control before consignment.

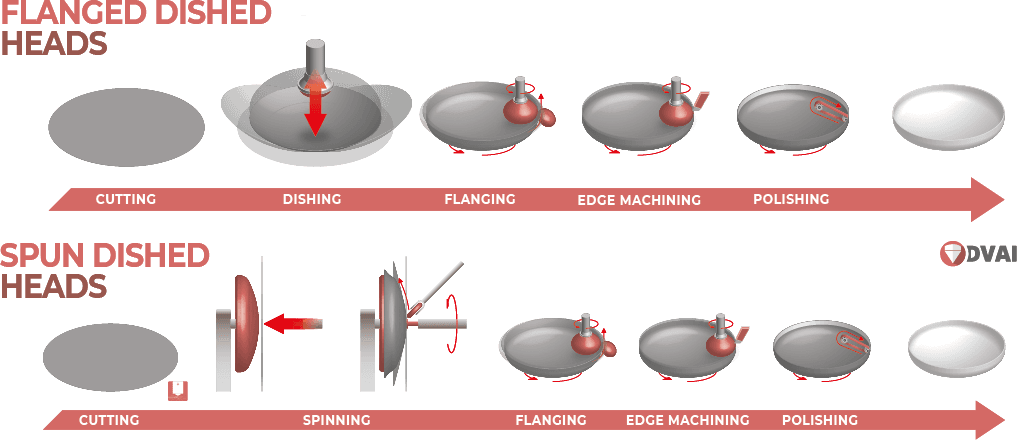

Flanged dished heads

DVAI can manufacture tank heads by flanging, following the steps outlined in the diagram below. Flanging has the advantage of achieving any dimension freely.

Spun dished heads

The manufacture by spinning imposes the constraint of working against a tool. All dimensions are not possible due to lack of tools or require a new particular tool, consequently this point can strongly influence the cost of each spun piece.

Technical information about tank heads

DVAI is able to create in its workshops heads of very varied profiles and some of them meet specific and sometimes standardized technical criteria.

Referenced norms

Dished heads are manufactured according to the following norms:

– NF E 81-100 December 1997 – Dished heads, designation, tolerances.

– German tolerances DIN28011 et DIN28013

DVAI manufactures the following type of heads:

- PRC Small knuckle radius head N FE 81-101 or Shallow Head

- GRC Large knuckle radius head N FE 81-102 or Torispherical head DIN28011

- Elliptical head N FE 81-103 or Semi Ellipsoidal Head DIN28013

- MRC Medium knuckle radius head N FE 81-104

Edge machining and bevelling are made according to the N FE81-110.